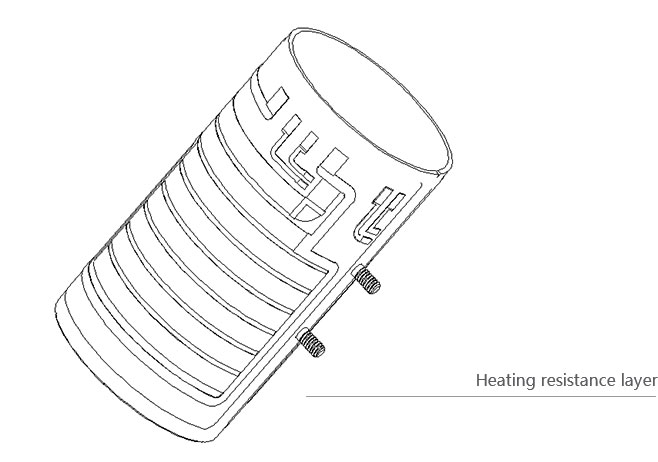

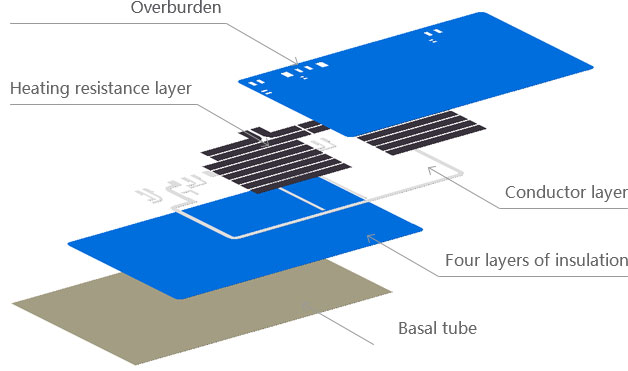

Stainless steel thick film heating technology is a new heating technology mainly developed by DuPont company of the United States and Hercules company of Germany in the late 1990s. They took the lead in developing electronic paste that can be used on stainless steel substrate. They use screen printing technology to print and sinter insulating medium, conductor circuit, resistance circuit and protective layer on stainless steel substrate, Thus, a new type of high-power heating element is obtained.

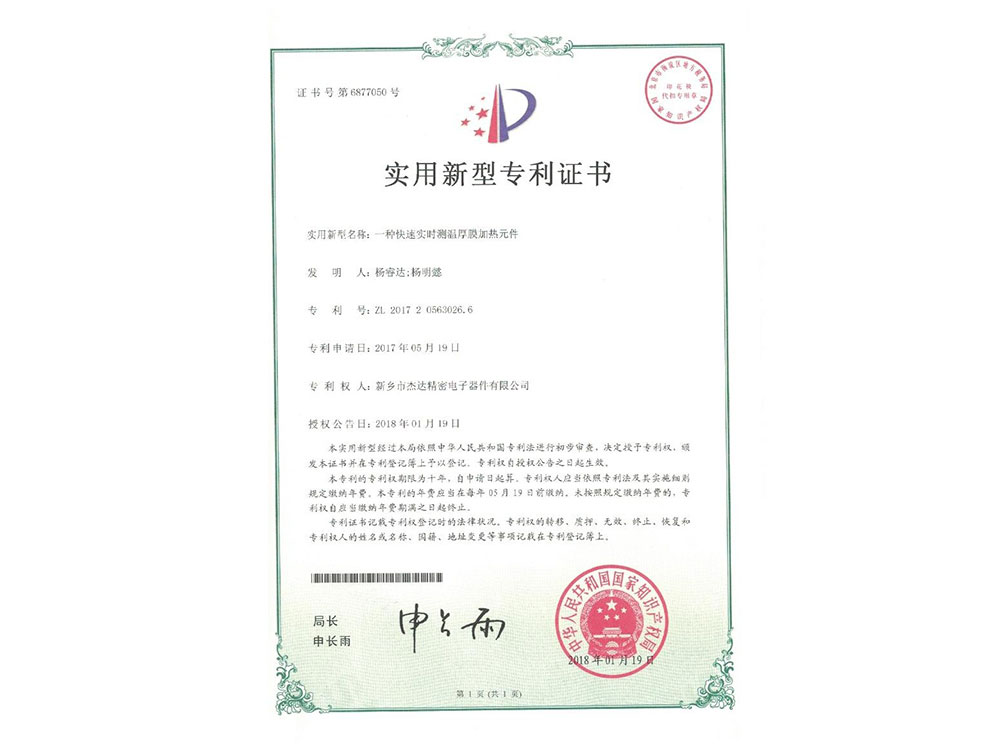

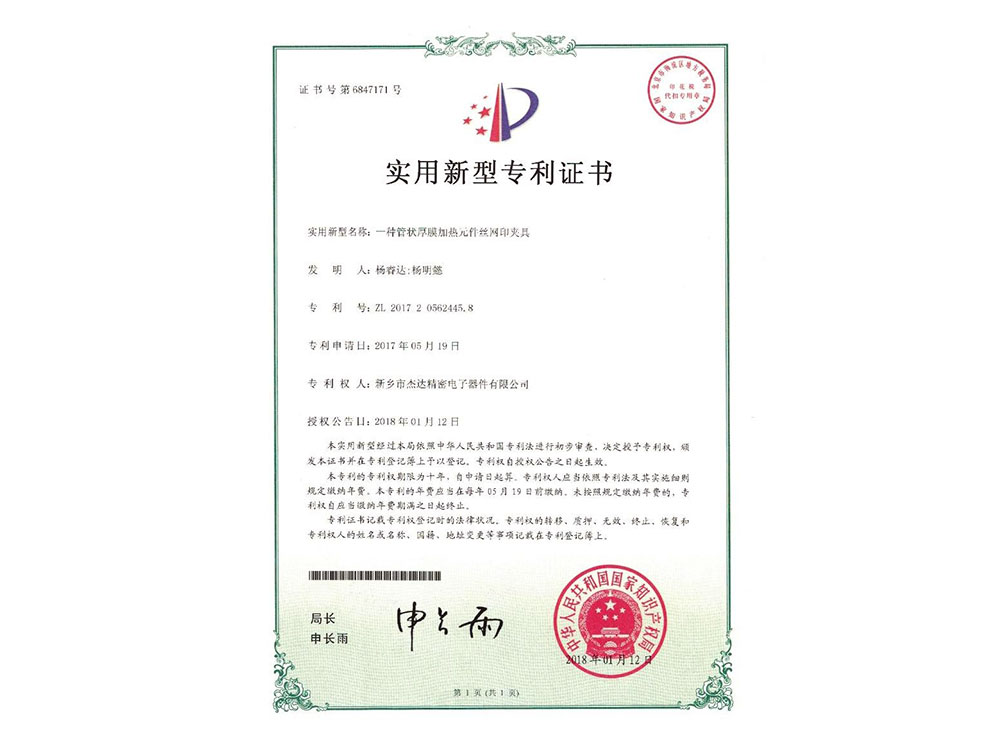

The domestic stainless steel thick film heating technology began to develop from the heating plate. Jeddah company took the lead in focusing on the research and development of thick film heating tubes. It is the first enterprise in China to realize the mass production and application of stainless steel thick film heating tubes.